INDIAN ARMED FORCES CHIEFS ON

OUR RELENTLESS AND FOCUSED PUBLISHING EFFORTS

SP Guide Publications puts forth a well compiled articulation of issues, pursuits and accomplishments of the Indian Army, over the years

I am confident that SP Guide Publications would continue to inform, inspire and influence.

My compliments to SP Guide Publications for informative and credible reportage on contemporary aerospace issues over the past six decades.

- Prime Minister witnesses 'Bharat Shakti' – a Tri-Services Firing and Manoeuvre Exercise in Pokhran, Rajasthan

- Interim Defence Budget 2024-25 — An Analysis

- Union Defence budget 2024

- Prime Minister Modi Commemorates Indian Navy Day in a Grand Ceremony

- Prime Minister Modi Flies in the LCA Tejas

- New Chapter in India-Italy Defence Ties

- Airpower beyond Boundaries

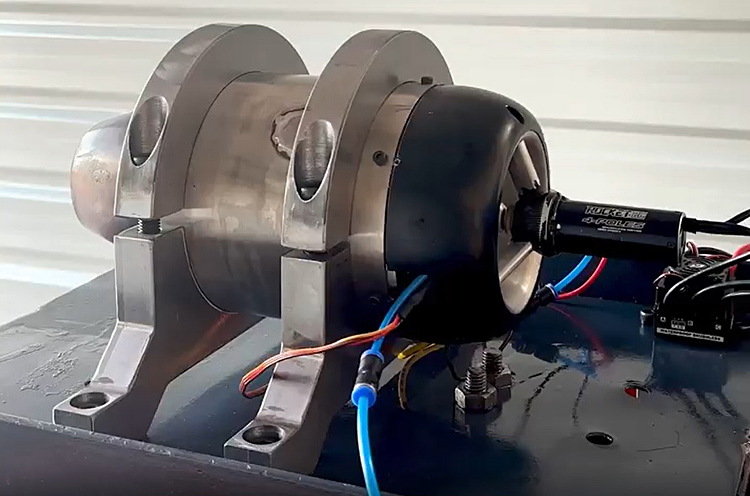

Indigenous Engines

A historic leap in indigenous engine technologies is empowering India's defence

|

The Author is Former Director General of Information Systems and A Special Forces Veteran, Indian Army |

The defence public sector undertaking (DPSU) Bharat Earth Movers Limited (BEML) achieved an important milestone on March 20, 2024, when it successfully test-fired India's first indigenously made 1500 HP engine for the main battle tanks (MBTs). The test-firing was conducted at BEML's engine division in the presence of Defence Secretary Giridhar Aramane. This is a significant achievement since India has been lacking indigenous engine-related technology all these decades.

Inaugurating the Test Cell, the Defence Secretary described the achievement as a transformative moment that will enhance the capabilities of the Armed Forces. BEML CMD Shantanu Roy stated that the accomplishment solidifies BEML's position as a key contributor to defence production in the country, underscoring its commitment to serving the nation's needs in this critical sector. The project, initiated in August 2020, had been meticulously structured into five major milestones, ensuring timely completion and adherence to quality standards. The Defence Secretary also inaugurated the 'Wall of Fame' to recognise the extraordinary efforts of the BEML team, symbolising their contribution towards advancing the defence capabilities of the country and achieving milestones in indigenous technological innovation.

BEML achieved an important milestone on March 20, 2024, when it successfully test-fired India's first indigenously made 1500 HP engine for the main battle tanks (MBTs)

On the successful test-firing of the 1500 HP engine, the Ministry of Defence (MoD) issued a statement saying, "The achievement heralds a new era in the country's defence capabilities, showcasing the technological prowess and commitment to self-reliance in defence technologies. The engine represents "a paradigm shift in military propulsion systems, possessing cutting-edge features such as high power-to-weight ratio, operability in extreme conditions including high altitudes, sub-zero temperatures and desert environments. Equipped with advanced technologies, the engine stands on par with the most advanced engines globally."

With reference to the phases for development of the engine, the MoD said, "The first test-firing of the 1500 HP engine signifies the completion of Generation One, focusing on technology stabilisation. Generation Two will see BEML producing engines for various trials at Combat Vehicles Research and Development Establishment, a DRDO laboratory, and their integration into actual vehicles for user testing. The project is slated for completion by mid-2025."

Generation Two will see BEML producing engines for various trials at CVRDE, and their integration into actual vehicles for user testing. The project is slated for completion by mid-2025.

As the saying goes "the proof of the pudding lies in its eating". The production of the first generation of BEML's 1500 HP engine engines has already begun, with 20 such engines set to undergo further trials in the next year. All eyes will now be on performance of the BEML's 1500 HP engine into user vehicles/MBTs and successful user trials. Hopefully, the project will be completed by mid-2025, as planned.

The second void in India is in the field of aero engines. DRDO's Kaveri engine (GTX-35VS), developed by the Bengaluru-based Gas Turbine Research Development (GTRE), was originally intended to power production models of the Tejas Light Combat Aircraft (LCA) developed by Hindustan Aeronautics Limited (HAL). Full-scale development of the Kaveri engine was authorised in April 1989 in what was then expected to be a 93-month programme projected to cost ₹3.82 billion ($47.8 million). The original plans called for 17 prototype test engines to be built. By 2002, little information was released about technical challenges faced by the Kaveri engine but it was known that it was encountering failure of the turbine blades. The Kaveri programme failed to satisfy the necessary technical requirements and keeping up with the envisaged timelines and was officially delinked from the Tejas LCA programme in September 2008.

A dry variant of the Kaveri engine is being developed to power DRDO's 'Ghatak' autonomous jet powered UCAV under development by the Aeronautical Development Establishment (ADE)

After being on hold for nearly a decade a dry variant of the Kaveri engine is reportedly being developed to power DRDO's 'Ghatak' autonomous jet powered unarmed combat air vehicle (UCAV) under development by the Aeronautical Development Establishment (ADE). A trial flight of a Stealth Wing Flying Test-bed (SWIFT), which is a scaled down technology demonstrator of the Ghatak' UCAV, was carried out in July 2022 and a full scale 'prototype' is expected in 2025.

Good news is that Indian aerospace startup DG Propulsion Private Limited (DPPL) marked a major success with its indigenously developed DG J40 jet engine, according to news reports of February 28, 2024. The engine, capable of producing 40 kgf of thrust, surpassed expectations during a rigorous one-hour endurance test, demonstrating its potential for diverse applications. DPPL's Director Prateek Dhawan said, "We exceeded the highly sought-after one-hour mark – one-hour and 10 minutes to be precise."

Indian aerospace startup DG Propulsion Private Limited (DPPL) marked a major success with its indigenously developed DG J40 jet engine that demonstrated exceptional stability and reliability throughout the trial despite being subjected to challenging conditions

The J40 jet engine demonstrated exceptional stability and reliability throughout the trial despite being subjected to challenging conditions, including fluctuating throttle settings and rapid RPM changes, to thoroughly test its limits. While fuel constraints ended the test, Dhawan is confident in the engine's even greater capabilities. This successful endurance test marks a turning point for India's aerospace industry. The J40's capabilities are well-suited to power UAVs/UCAVs; allowing for greater range, enhanced payload capacity, and increased flexibility across military and civilian applications. DPPL's achievement underscores the growing capabilities of Indian startups within the aerospace sector.

In 2023, India had inked a deal with the US to jointly produce GE Aviation's F414 engines in India. This includes transfer of technology (ToT) as per the agreement between Hindustan Aeronautics Limited (HAL) and America's GE, in line with manufacturing GE's F414-INS6 engines in India. According to media reports, the first two IAF squadrons of the indigenous advanced medium combat aircraft (AMCA) are also to be powered by the GE F414 engines. The GE F414 technology transfer is supposed to be 100 per cent, although getting delayed for inexplicable reasons. Whether the 100 per cent ToT will include the inner core of the engine also remains doubtful. In fact, 99 per cent ToT may happen if the US-led West perceives that India is on the cusp of developing aero-engine technology on its own. This is what the DRDO and our private industry must focus on.