INDIAN ARMED FORCES CHIEFS ON OUR RELENTLESS AND FOCUSED PUBLISHING EFFORTS

The insightful articles, inspiring narrations and analytical perspectives presented by the Editorial Team, establish an alluring connect with the reader. My compliments and best wishes to SP Guide Publications.

"Over the past 60 years, the growth of SP Guide Publications has mirrored the rising stature of Indian Navy. Its well-researched and informative magazines on Defence and Aerospace sector have served to shape an educated opinion of our military personnel, policy makers and the public alike. I wish SP's Publication team continued success, fair winds and following seas in all future endeavour!"

Since, its inception in 1964, SP Guide Publications has consistently demonstrated commitment to high-quality journalism in the aerospace and defence sectors, earning a well-deserved reputation as Asia's largest media house in this domain. I wish SP Guide Publications continued success in its pursuit of excellence.

- Operation Sindoor: Resolute yet Restrained

- India’s Operation Sindoor Sends a Clear Message to Terror and the World – ‘ZERO TOLERANCE’

- Japan and India set forth a defence cooperation consultancy framework, talks on tank and jet engines

- Terrorist Attack in Pahalgam in Kashmir: Unfolding a long surgical war against PAK

- Lt General Pratik Sharma takes over Command of Indian Army's Northern Command

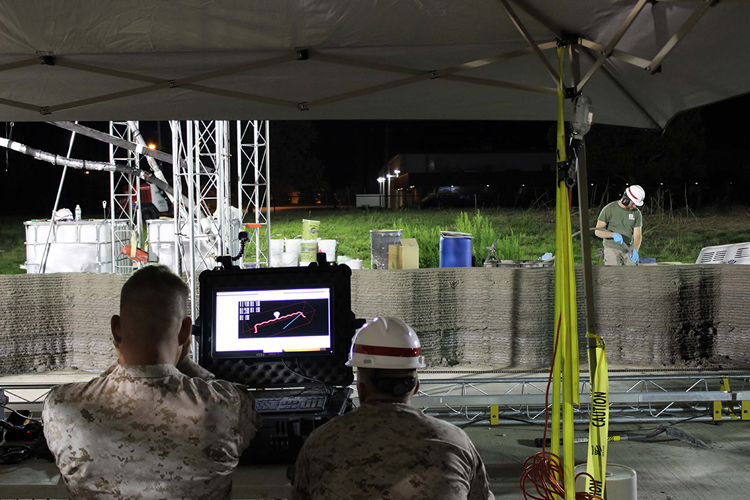

3D Printing in War

Additive manufacturing, already adopted by the US military, offers flexibility, cost savings, and reduced logistical challenges by enabling the production of spare parts and tools on-demand

|

The Author is Former Director General of Information Systems and A Special Forces Veteran, Indian Army |

It was reported in these columns in December 2022 that the Indian Army had created permanent defences using 3D technology and had conducted successful trials. 3D printing, also referred to as 'additive manufacturing' (AM) is a technology that uses complex software and robotic units that helps in creating a structure through multiple stages from a digital model; it's a process of joining materials to make parts from 3D model data, usually layer by layer.

Trials of these 3D defences were successfully carried out against a range of weapons from small arms to the main gun of the T-90 tank. During the trials, these defences withstood direct fire by a T-90 tank from a distance of about 100 metres. These structures are modern, compact, and can be lifted and erected in a few days. Moreover, they save time, cut costs and can also be relocated. On December 28, 2022 the Indian Army also inaugurated its first 3D Printed House Dwelling Unit (with Ground plus One configuration) for soldiers at Ahmedabad Cantonment.

The Indian Army has successfully tested 3D-printed defences that withstood direct fire from a T-90 tank and are now being used to build modular bunkers and underground facilities along the border with China

Since then, the Indian Army has been in the process of constructing modular, 3D-printed, next generation bunkers to provide better protection to front-line soldiers guarding the country's border with China in the Ladakh sector, as also creating underground facilities for the storage of ammunition at forward locations along the Line of Actual Control (LAC). These defences can be easily moved by two soldiers if needed as the heaviest component in the structure weighs only 40 kg. Durability and lightness are the benefits of the bunkers. The modules are being built by the Army's Corps of Engineers in partnership with the IITs at Gandhinagar and Madras.

Drawing lessons from the protracted war in Ukraine, as well as the war in Gaza, the Israel-Hezbollah war, the US-UK-Israeli operations against Houthi and the like, the Indian Military is examining the use of 3D printing in war. This is a much needed step because the threats to India are rising by the day, Talibanisation of Bangladesh has added to the existing multi-front war, and there is every possibility of India getting involved in a protracted war, given the fact that the US wants an India-China war, using India as a Western proxy – akin to Ukraine.

3D printing is already being used by terrorist, non-state actors and rebels. Rebels in Myanmar are using 3D printed drones en-masse to catalyse the civil war against the military junta. 3D printers are producing in-house weapons for the rebels, including drones, mortar stabilisers, and other munitions. Ukraine's cheap drones have revolutionised the way wars are fought, but the use of 3D printers drones in Myanmar has further shown that wars can be prolonged on a shoestring budget. Myanmar rebels have been using 3D-printed swarm drones (Liberator Mk-1 and Liberator Mk-2) and FGC-9 3D-printed semiautomatic rifles using the moniker JStark1809 as the blueprint for the weapon.

3D printing is being explored by the Indian Military for its potential in protracted wars, given its use by rebels and terrorists for manufacturing drones, weapons, and other munitions

The US Marine Corps can use 3D to print a sensor housing to secure a gap in the perimeter of a base; Army field repair units print a low-cost cap to protect a million-dollar lens on a tank, and the US Air Force is using AM to replace obsolete parts for the C-5 at five percent of the cost. The US Navy has installed two different kinds of metal 3D printers on its ships, with an aluminum system on the west coast, and a stainless steel system on the east coast. It is not practical for the Navy to carry every replacement part for every system on a ship, and it can be difficult to forecast if or when parts will fail.

Additive manufacturing provides a flexible source of supply in being able to make parts instead of ordering them and waiting for them to arrive, especially for warships at the far end of the supply chain. Printing repair parts on demand can save time, lower costs and reduce the need to carry extensive parts inventories. Desktop 3D printers are widely available, starting at about $300 for a home system. Many ships have 3D printers that make relatively small plastic parts.

In 2024, Indian space startup Agnikul Cosmos successfully launched the nation's first 3D-printed rocket engine; a capability that has numerous applications. 3D printing a motor could take a mere 3-4 days, compared to the 3-4 weeks through precision manufacturing. India has an expanding list of 3D printing service providers like Imaginarium, Wipro 3D, 3Ding and THINK3D, among others and the market has shown significant growth. The Defence Research and Development Organisation (DRDO) is reportedly exploring 3D printing with private sector players.

The Indian space startup Agnikul Cosmos successfully launched the nation's first 3D-printed rocket engine, showcasing the technology's rapid production capabilities and potential for wide applications

3D printing techniques can be beneficial for missiles such as very short-range air defence systems (VSHORADS) and Man Portable Anti-Tank Guided Missiles (ATGMs), in addition to weapon parts, which can drastically cut down the supply chain. The advantages of this technology in a protracted war can hardly be overemphasized.

3D Printing creates the part and material simultaneously. This improves production speed and flexibility but requires careful control of the additive manufacturing process. It can be used to build parts that cannot be made any other way, uniquely combine materials, produce obsolete parts, rapidly prototype, and create tools and specialised job aids.

The preponderance of drones in modern wars is being witnessed all over. Both Russia and Ukraine are using one-way attack (OWA) 3D printed drones. Unlike most armed drones, which drop one or more bombs and return for further use, a one-way attack drone (also referred to as a kamikaze drone) flies to its target and detonates on or above it, destroying the drone in the process,

The 'Drone Coalition of NATO-EU, spearheaded by the UK and Latvia, represents a coordinated initiative to deliver one million First Person View (FPV) drones to Ukraine. Beyond FPV drones, the coalition also commits to supplying an array of reconnaissance, strike, and AI-enhanced drones alongside counter-drone technologies. The team assembles the components in a Kyiv workshop and sends the finished product to the front using a commercial package service. Vladyslav Ripko's day job is working for the Ukrainian government as a financial analyst. But in the evenings and on weekends, he and his friends make drones for the Ukrainian army.

The growing threat of 3D-printed drones in modern warfare, highlighted by Russia and Ukraine's use of one-way attack drones, shows how drones are reshaping conflict scenarios

Russia has recently announced that next year Russian Armed Forces (RuAF) will receive 10 times the drones provided this year. In 2023, 1,40,000 drones were delivered to the RuAF. This increased to tenfold in 2024 – to 11,40,000 drones in 2024. Russia is streamlining production and drone supply with governmental initiatives and help of volunteer organisations. Notably, the RuAF staffing is being increased to 2,389,000 , in the military of 1.5 million, which is the world's second largest military.

Finally, all this shows the gigantic task that we face in adopting 3D printing for war, especially for a protracted one, as well as coping with use of drones by inimical forces in the no-war-no-peace scenario. This needs a well planned, closely integrated national effort.