INDIAN ARMED FORCES CHIEFS ON OUR RELENTLESS AND FOCUSED PUBLISHING EFFORTS

The insightful articles, inspiring narrations and analytical perspectives presented by the Editorial Team, establish an alluring connect with the reader. My compliments and best wishes to SP Guide Publications.

"Over the past 60 years, the growth of SP Guide Publications has mirrored the rising stature of Indian Navy. Its well-researched and informative magazines on Defence and Aerospace sector have served to shape an educated opinion of our military personnel, policy makers and the public alike. I wish SP's Publication team continued success, fair winds and following seas in all future endeavour!"

Since, its inception in 1964, SP Guide Publications has consistently demonstrated commitment to high-quality journalism in the aerospace and defence sectors, earning a well-deserved reputation as Asia's largest media house in this domain. I wish SP Guide Publications continued success in its pursuit of excellence.

- Operation Sindoor: Resolute yet Restrained

- India’s Operation Sindoor Sends a Clear Message to Terror and the World – ‘ZERO TOLERANCE’

- Japan and India set forth a defence cooperation consultancy framework, talks on tank and jet engines

- Terrorist Attack in Pahalgam in Kashmir: Unfolding a long surgical war against PAK

- Lt General Pratik Sharma takes over Command of Indian Army's Northern Command

Indigenous AIP System

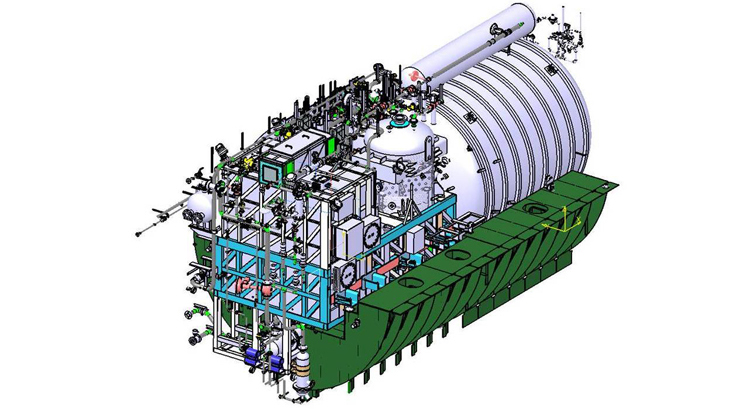

Mazagon Dock Shipbuilders Limited (MDL) has marked the commencement of production for the first Air Independent Propulsion (AIP) system for the Indian Navy's Scorpene-class submarines

|

The Author is Former Director General of Information Systems and A Special Forces Veteran, Indian Army |

Air-independent propulsion (AIP), or air-independent power, is any marine propulsion technology that allows a non-nuclear submarine to operate without access to atmospheric oxygen (by surfacing or using a snorkel). AIP can augment or replace the diesel-electric propulsion system of non-nuclear vessels. Modern non-nuclear submarines are potentially stealthier than nuclear submarines; although some modern submarine reactors are designed to rely on natural circulation, most naval nuclear reactors use pumps to constantly circulate the reactor coolant, generating some amount of detectable noise. Non-nuclear submarines running on battery power or AIP, on the other hand, can be virtually silent. AIP is usually implemented as an auxiliary source, with the traditional diesel engine handling surface propulsion.

Air-independent propulsion (AIP) allows a non-nuclear submarine to operate without access to atmospheric oxygen

AIP can be retrofitted into existing submarine hulls by inserting an additional hull section. AIP does not typically provide the endurance or power to replace atmospheric dependent propulsion, but allows for longer underwater endurance than a conventionally propelled submarine. A typical conventional power plant provides three megawatts maximum, and an AIP source around 10 per cent of that. A nuclear submarine's propulsion plant is usually much greater than 20 megawatts.

The Chinese People's Liberation Army Navy (PLAN) uses Air Independent Propulsion (AIP) technology, specifically in its Yuan-class (Type 039A) submarines, which are the first AIP-powered submarines in the PLAN. The Yuan-class SSK is integrated with advanced noise reduction techniques including anechoic tiles, passive/active noise reduction, asymmetrical seven-blade skewed propeller, the 039A is expected to be as quiet as other modern diesel-electric submarines, which are difficult to track.

The Indian Navy doesn't operate a single AIP-equipped submarine yet. In comparison, Pakistan Navy's all three French Agosta-90B (PNS Khalid, Saad, and Hamza) are powered by the French-supplied MESMA (Module d'Energie Sous-Marin Autonome) AIP system. Moreover, the Chinese Hangor submarines are expected to join the Pakistan Navy by the late 2020s and early 2030s. Upon completion, the submarines will join the Pakistan Navy's fleet, taking the strength of its AIP-equipped boats to 11. Pakistan has also accelerated its efforts to have one of Asia's largest naval fleets by enlarging its surface fleet to 50 warships along with a subsurface fleet of 11 submarines. Of the 50 surface ships the Pakistan Navy aspires to operate, 20 are expected to be major surface vessels like frigates and corvettes.

The Indian Navy doesn't operate a single AIP-equipped submarine yet

China is expanding its submarine presence in the Indian Ocean and Pakistan's expanding naval capabilities with their improved stealth, manoeuvrability, firepower and enhanced underwater endurance of AIP, would allow a wide range of operations effectively. India's need for advanced underwater stealth platforms has never been greater.

According to reports of March 19, 2025, the Mazagon Dock Shipbuilders Limited (MDL) has marked the commencement of production for the first Air Independent Propulsion (AIP) system for the Indian Navy's Scorpene-class submarines, having held the production plate cutting ceremony at MDL's facilities in Mumbai. The ceremony signalled the start of construction for the AIP plug, a critical enhancement designed to boost the underwater endurance of the Scorpene-class submarines under Project 75 (P-75). This indigenous AIP system developed by the Defence Research and Development Organisation (DRDO) in partnership with Indian industry will be integrated into the submarines during their scheduled normal refits, beginning with INS 'Kalvari' in September 2025.

This indigenous AIP system will be integrated into the submarines during their scheduled normal refits, beginning with INS 'Kalvari' in September 2025

The AIP system being constructed at MDL indicates the advances made by the DRDO's Naval Materials Research Laboratory (NMRL). The system uses a phosphoric acid fuel cell (PAFC) to generate power, offering a reliable and efficient alternative to foreign AIP technologies like the French MESMA (Module dEnergie Sous-Marine Autonme). Unlike earlier plans to import AIP systems, the Indian Navy has opted for this home-grown solution, reflecting confidence in its performance and adaptability.

The construction process will involve fabricating an 8-10 metre AIP plug, weighing approximately 300 tonnes, which will be retrofitted into the submarine hulls. This complex procedure requires cutting the submarine into two halves and inserting the new section – a task that the MDL with assistance from the Naval Group is well equipped to handle. The first integration will occur during INS Kalvari's refit, serving as a testbed for the technology before its rollout to the remaining five Scorpene submarines, INS 'Khanderi', INS 'Karanj', INS 'Vela', INS 'Vagir' and INS 'Vagsheer'. The induction of AIP-equipped submarines will significantly bolster the Indian Navy's underwater capabilities at a time when regional security dynamics are shifting.

Given China's and Pakistan's AIP-enabled submarine fleet, India's need for advanced underwater stealth platforms has never been greater

India's need for advanced underwater stealth platforms has never been greater. The AIP system will enable prolonged surveillance and deterrence missions in critical areas like the Bay of Bengal, the Arabian Sea, and the eastern Indian Ocean, enhancing India's maritime dominance. The deployment also strengthens MDL's position as a global leader in submarine construction. The AIP plug construction leverages MDL's state-of-the-art facilities, including the recently inaugurated AIP Integration and Testing Facility at the AM Naik Heavy Engineering Complex, ensuring that the system meets rigorous operational standards.