INDIAN ARMED FORCES CHIEFS ON OUR RELENTLESS AND FOCUSED PUBLISHING EFFORTS

The insightful articles, inspiring narrations and analytical perspectives presented by the Editorial Team, establish an alluring connect with the reader. My compliments and best wishes to SP Guide Publications.

"Over the past 60 years, the growth of SP Guide Publications has mirrored the rising stature of Indian Navy. Its well-researched and informative magazines on Defence and Aerospace sector have served to shape an educated opinion of our military personnel, policy makers and the public alike. I wish SP's Publication team continued success, fair winds and following seas in all future endeavour!"

Since, its inception in 1964, SP Guide Publications has consistently demonstrated commitment to high-quality journalism in the aerospace and defence sectors, earning a well-deserved reputation as Asia's largest media house in this domain. I wish SP Guide Publications continued success in its pursuit of excellence.

- Indian Air Force Aims for Full Indigenous Inventory by 2047 — Air Chief Marshal A.P. Singh

- General Upendra Dwivedi takes over as the Chief of the Army Staff

- Rajnath Singh assumes charge as Defence Minister for the second consecutive term

- Admiral Dinesh K. Tripathi assumes Command of the Indian Navy as 26th Chief of the Naval Staff

- Prime Minister witnesses 'Bharat Shakti' – a Tri-Services Firing and Manoeuvre Exercise in Pokhran, Rajasthan

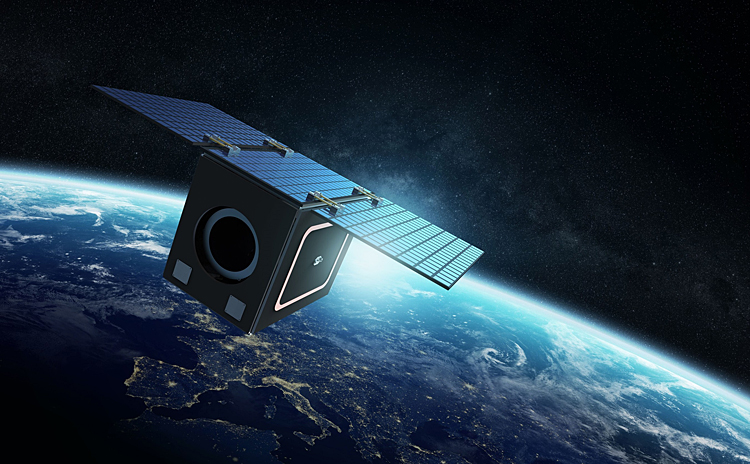

Boeing Sets Rapid Pace with 3D-Printed Solar Array Substrates

- Technical innovation cuts production cycle time by up to six months

- First 3D-printed solar arrays will fly Spectrolab solar cells aboard small satellites built by Millennium Space Systems

- Designed to scale from smallsats to Boeing 702-class platforms

Boeing unveiled a 3D printed solar array substrate approach that compresses composite build times by up to six months on a typical solar array wing program from print to final assembly. This represents a production improvement of up to 50 per cent when compared to current cycle times.

Flight representative hardware has completed engineering testing and is progressing through Boeing's standard qualification path ahead of customer missions.

"Power sets the pace of a mission. We reached across our enterprise to introduce efficiencies and novel technologies to set a more rapid pace," said Michelle Parker, vice president of Boeing Space Mission Systems. "By integrating Boeing's additive manufacturing expertise with Spectrolab's high efficiency solar tech and Millennium's high rate production line, our Space Mission Systems team is turning production speed into a capability, helping customers field resilient constellations faster."

The first 3D-printed solar arrays will fly Spectrolab solar cells aboard small satellites built by Millennium Space Systems. Both non-integrated subsidiaries are part of Boeing's Space Mission Systems organization.

Beyond the arrays themselves, Boeing's approach enables a parallel build of the complete array, pairing a printed, rigid substrate with flight-proven modular solar technologies.

By printing features such as harness paths and attachment points directly into each panel, the design replaces dozens of separate parts, long lead tooling, and delicate bonding steps with one strong, precise piece that is faster to build and easier to integrate. It is built upon the foundation of Boeing's qualified additive, flight-proven materials and processes.

"As we scale additive manufacturing across Boeing, we're not just taking time and cost out, we're putting performance in," said Melissa Orme, vice president, Materials & Structures, Boeing Technology Innovation. "By pairing qualified materials with a common digital thread and high rate production, we can lighten structures, craft novel designs, and repeat success across programs. That's the point of enterprise additive, it delivers better parts today and the capacity to build many more of them tomorrow."

Across the Boeing portfolio, the company has incorporated more than 150,000 3D printed parts, yielding significant schedule, cost, and performance benefits. This includes more than 1,000 radio-frequency parts on each Wideband Global SATCOM (WGS) satellite currently in production and multiple small satellite product lines with fully 3D printed structures.

The new array approach is designed to scale from small satellites to larger platforms, including Boeing 702 class spacecraft, targeting market availability for 2026.

By printing the panel's structure and built in features, Boeing can assemble the array in parallel with cell production. Robot assisted assembly and automated inspection at Spectrolab further reduce handoffs, improving speed and consistency.