INDIAN ARMED FORCES CHIEFS ON OUR RELENTLESS AND FOCUSED PUBLISHING EFFORTS

The insightful articles, inspiring narrations and analytical perspectives presented by the Editorial Team, establish an alluring connect with the reader. My compliments and best wishes to SP Guide Publications.

"Over the past 60 years, the growth of SP Guide Publications has mirrored the rising stature of Indian Navy. Its well-researched and informative magazines on Defence and Aerospace sector have served to shape an educated opinion of our military personnel, policy makers and the public alike. I wish SP's Publication team continued success, fair winds and following seas in all future endeavour!"

Since, its inception in 1964, SP Guide Publications has consistently demonstrated commitment to high-quality journalism in the aerospace and defence sectors, earning a well-deserved reputation as Asia's largest media house in this domain. I wish SP Guide Publications continued success in its pursuit of excellence.

- Indian Air Force Aims for Full Indigenous Inventory by 2047 — Air Chief Marshal A.P. Singh

- General Upendra Dwivedi takes over as the Chief of the Army Staff

- Rajnath Singh assumes charge as Defence Minister for the second consecutive term

- Admiral Dinesh K. Tripathi assumes Command of the Indian Navy as 26th Chief of the Naval Staff

- Prime Minister witnesses 'Bharat Shakti' – a Tri-Services Firing and Manoeuvre Exercise in Pokhran, Rajasthan

Hiding in plain sight

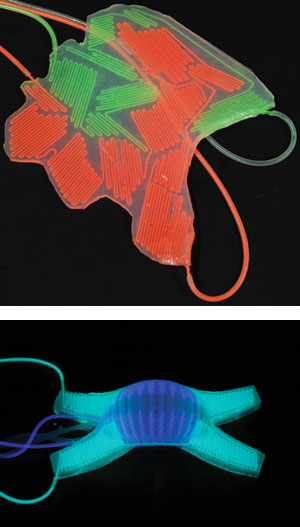

Hiding in plain sight This robot is made of silicone. It can walk, change colour and light up in the dark. It can even change temperature. And it can do all of this for less than $100. In the future, robots like this might be made for just a few dollars.

Researchers led by Dr George Whitesides and Dr Stephen Morin at Harvard University’s Department of Chemistry and Chemical Biology and the Wyss Institute for Biologically Inspired Engineering demonstrated that microfluidic channels in soft robots enable functions including actuation, camouflage, display, fluid transport and temperature regulation. The work is being performed under DARPA’s Maximum Mobility and Manipulation (M3) programme.

Why does this matter to the Department of Defense (DoD)? DARPA foresees robots of many shapes and sizes contributing to a wide range of future defence missions, but robotics is still a young field that has focused much of its attention so far on complex hardware. Consequently, the costs associated with robotics are typically very high. What DARPA has achieved with silicone-based soft robots is development of a very low cost manufacturing method that uses molds. By introducing narrow channels into the molds through which air and various types of fluids can be pumped, a robot can be made to change its colour, contrast, apparent shape and temperature to blend with its environment, glow through chemiluminescence, and most importantly, achieve actuation, or movement, through pneumatic pressurisation and inflation of the channels. The combination of low cost and increased capabilities means DARPA has removed one of the major obstacles to greater DoD adoption of robot technology.

Gill Pratt, the DARPA programme manager for M3, put the achievement in context: “DARPA is developing a suite of robots that draw inspiration from the ingenuity and efficiency of nature. For defense applications, ingenuity and efficiency are not enough—robotic systems must also be cost-effective. This novel robot is a significant advance towards achieving all three goals.”

Soft robots are useful because they are resilient and can manoeuvre through very constrained spaces. For this demonstration, the researchers used tethers to attach the control system and pump pressurised gases and liquids into the robot. Tethered operation reduces the size and weight of such robots by leaving power sources and pumps off-board, but future prototypes could incorporate that equipment in a self-contained system. At a pumping rate of 2.25 millilitres per minute, colour change in the robot required 30 seconds. Once filled, the colour layers require no power to sustain the colour.